Two of the most common reasons for cooling tower immersion heater failure:

- Immersion Heaters with Stainless Steel elements are awesome, but if exposed to high concentrations of cleaning agents which typically contain chlorine, once the elements are energized the corrosive nature of chlorine may rapidly accelerate corrosion to the elements and shorten the life of your heater.

Solution: Using a Brass rather than stainless steel fitting with Copper elements will generally offer much greater resistance and longer life when exposed to higher levels of chlorine.

- Another cause of immersion heater failure is that there may not be enough chemical to retard the formation of algae/sludge build-up which can create an insulation barrier which keeps the heat on the elements and prevents the heat from radiating through-out the basin water and over-heating the immersion heater elements to the point of premature element failure.

This Immersion heater (shown left) was buried in basin sludge and failed due to over-heating. Unfortunately, the cause of failure was not discovered until the basin was cleaned and the problem “uncovered”

This Immersion heater (shown left) was buried in basin sludge and failed due to over-heating. Unfortunately, the cause of failure was not discovered until the basin was cleaned and the problem “uncovered”

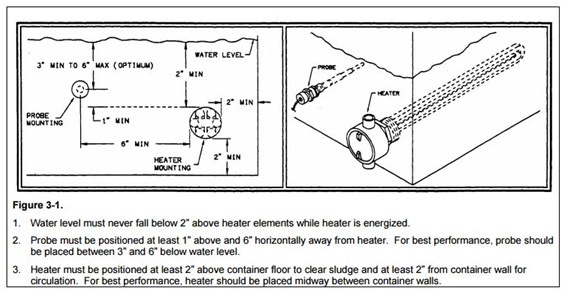

To help prevent premature immersion heater failure please note the minimum installation requirements (see diagram below). Following these guide lines will prolong the life of your heater as well as protect it from heavy sludge and algae build-up.

Thank you for reading “Cooling Tower Immersion Heater Failure and Installation Guide”. Stay tuned for more from the experts at Universal Tower Parts.

Universal Tower Parts In Phoenix, AZ

Universal Tower Parts provides stainless steel and galvanized options, welded and gasketed, direct, gear reducer and belt drive units, with efficient Jedair fans, and Jedair low noise fans. Strainers, fan guards and louvers are well constructed, and designed to operate efficiently as they perform their function. Cool Core drift eliminators and fill are made by Universal Tower Parts expressly for our towers.