Different types of cooling towers are designed for different types of purposes. Each individual type of cooling tower is made for a different application or industrial process. In this article, we will discover the different types of cooling towers and what type of applications for each cooling tower is made for. Let’s start by examining, what is a cooling tower?

“Cooling towers are a special type of heat exchanger that allows water and air to come in contact with each other to lower the temperature of the hot water. During the cooling tower working process, small volumes of water evaporate, lowering the temperature of the water that’s being circulated throughout the cooling tower.” Cooling Tower Products (How Cooling Towers Work (W/ Diagram, Pictures & Principles) 2016)

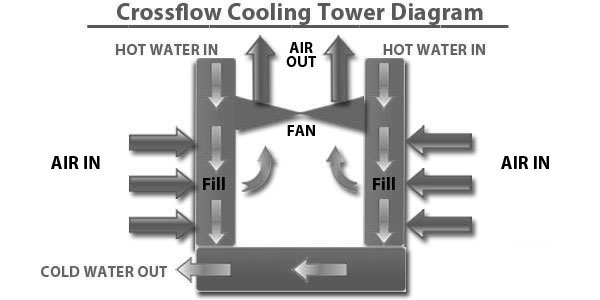

Crossflow Cooling Towers

Crossflow cooling towers work by water flowing vertically through fill media, while air flows horizontally across the water. Hince, the word crossflow, due to the air and water crossing paths. Due to the flow crossing, air does not need to pass through a distribution system. This allows hot water flow by gravity, while distribution basins at the top of the cooling tower are right above the fill media. Distribution basins come standard in every crossflow cooling tower.

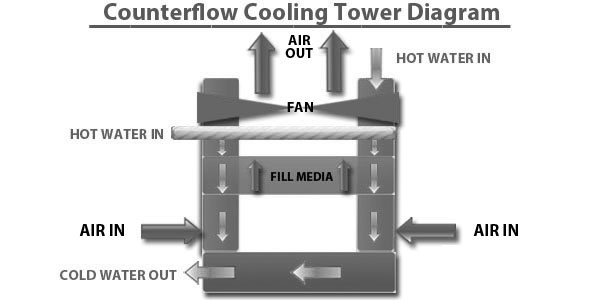

Counterflow Cooling Towers

Air flows upwards, vertically in counterflow cooling towers, while the water flows counter to inside the fill media. Due to vertically flowing air, this type of cooling tower cannot use gravity-flow like crossflow can. Instead, counterflow towers use spray systems that are pressurized to spray water on top of fill media. Also, the cooling tower nozzles and pipes are spread far apart to give extra room for air flow.

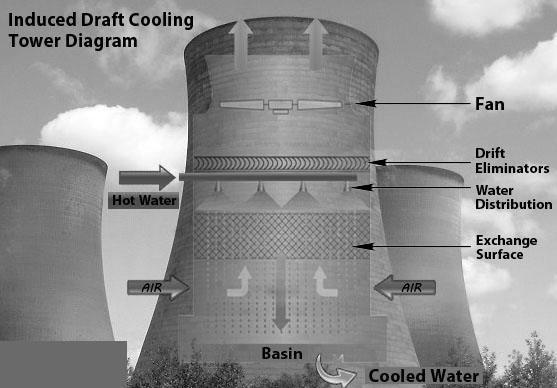

Induced Draft & Forced Draft Cooling Towers

Induced draft cooling towers use fans to pull air through fill media. Forced draft cooling towers on the other hand, pushed or forces air through blowers pulling from the bottom of the air inlet louver.

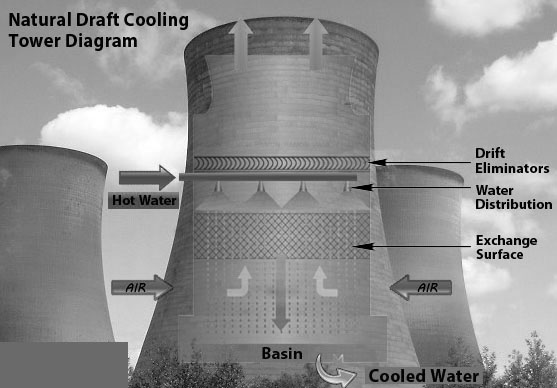

Natural Draft Cooling Towers

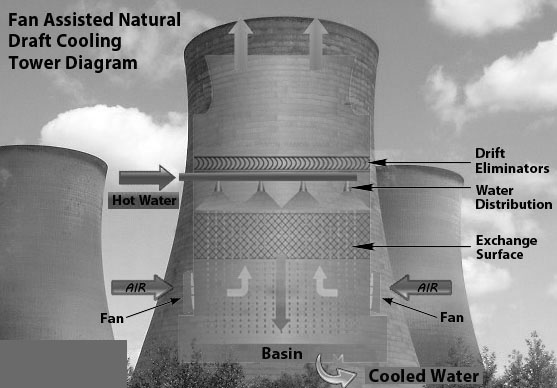

Fan Assisted Natural Draft Cooling Towers

(FAP) Factory Assembled Product | Factory Assembled Cooling Towers

FAP cooling towers are shipped in smaller section s to their final resting place to be assembled or erected in the field. Although, small FAP cooling towers can be shipped all in one unit. The different types of FAP cooling towers are induced draft, forced draft, crossflow, and counterflow, depending on the industrial application its used for. TCIA cooling towers are typically used for light industrial applications such as commercial heating, ventilation, and air conditioning.

Field Erected Product | Field-Erected-Towers (FEP)

FEP cooling towers are constructed on-site. Large Field erected cooling towers are prefabricated, marked individually piece by piece, then shipped to the site for assembly. The manufacturer of the cooling tower handles final assembly and labor that is involved. The different types of FEP cooling towers are crossflow or counterflow depending on the industrial application its used for.

If you have heavy industrial applications that need more cooling power, FEP cooling towers can be custom built to your exact needs, specifications, performance, structure, drift, and plume abatement.

What Are Cooling Towers?

Cooling towers are the backbone of many industrial and commercial ventures. Some industrial processes, especially fabrication, involved extreme heat. Just like in our engines the heat must be controlled and dissipated. Cooling towers are a lot like giant radiators that cool refrigerant back down so it can be used again to keep the equipment cold.

Cooling towers aren’t just used for fabrication and industrial processes. They are also used to help keep large commercial properties cool. They work in unison with chillers which super cool air. They produce heat and the cooling tower helps keep them cool.

For cooling towers to keep things under control they use nozzles to spray the hot refrigerant (usually water) over different types of structures which force the hot water to come into contact with air that is being passed through the cooling tower. This can happen either from above, or from the side depending on the design of the cooling tower.

How Cooling Towers Function

We know that cooling towers channel hot air to come into direct contact with flowing air. This can be achieved in a few different ways, but the principle is the same. The hot water is cooled back down after being through the industrial or HVAC process by being forced to come into contact with air flowing either up or sideways. Advanced fill material called film fill increases the duration the air and water come into contact and increase the thermal reduction of the coolant.

Air is channeled into and through the cooling tower via cooling tower fans, or through careful design of the cooling tower. Natural draft cooling towers rely on physics to cause air to enter and rise through the tower. When the hot air rises in one of these natural draft towers the air traveling up causes a vacuum and pulls air in through the base of the tower.

A small percentage of water is lost through evaporation, but this is limited with drift eliminators. Drift eliminators are parts of cooling towers that control how much water is lost due to evaporation, and splash out during the cooling process.

Once the water has completed its cycle through the cooling towers fill and flows down to the basin it is pumped back into the industrial system loop. This process is customized to current industrial load. Meaning if only a percentage of the equipment is running the cooling tower can have variable mode motors and systems that go into more energy efficient modes to help save power.

How Does Evaporative Cooling Work?

Our bodies are probably the easiest example for us to understand the effects of evaporative cooling. When we are hot we begin to sweat. The purpose of the sweat is to evaporate from our skin, which leaves the skin cooler. Cooling towers work along the same principle of introducing liquid to cause a reduction in heat. The water in this case directly carries the heat away from industrial or HVAC processes and deposits it in the cooling tower. The cooling tower’s “skin” is the fill material. The fill is where the rubber meets the road, or more specifically where the hot water meets the air.

Universal Tower Parts In Phoenix, AZ

Universal Tower Parts provides stainless steel and galvanized options, welded and gasketed, direct, gear reducer and belt drive units, with efficient Jedair fans, and Jedair low noise fans. Strainers, fan guards and louvers are well constructed, and designed to operate efficiently as they perform their function. Cool Core drift eliminators and fill are made by Universal Tower Parts expressly for our towers.